Product Description

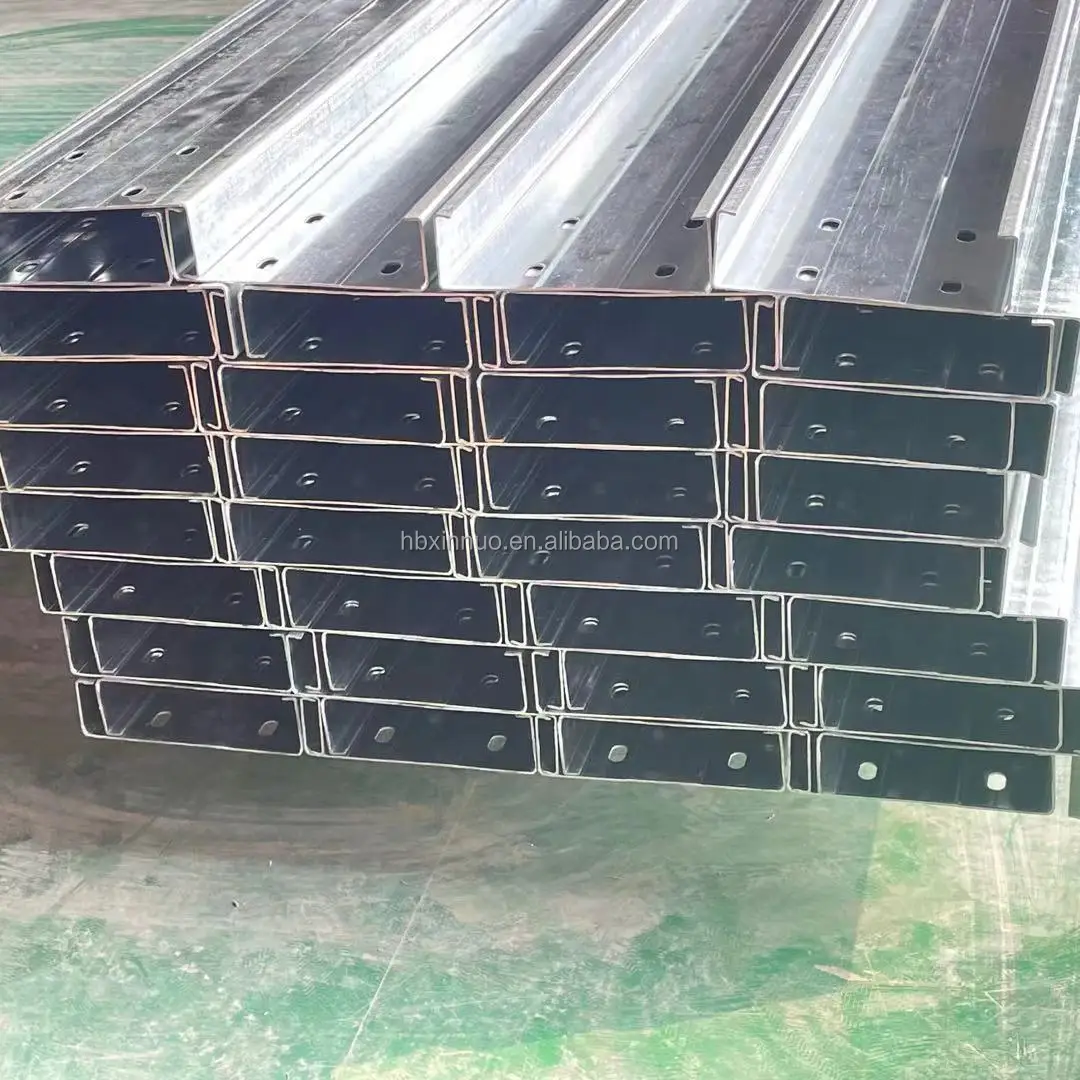

c purlin yob txoj kev siv tshuab

Specification

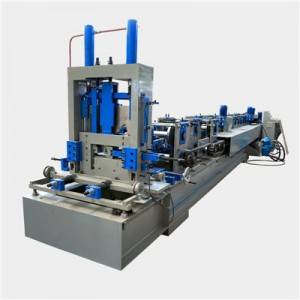

| 1. | Kev teeb tsa | Phau ntawv Uncoiler, Qhia Platform, 9 Ncej Sawb Leveler, Lub Tshuab Tseem Ceeb Ntawm Roll Forming, Hydraulic Tsav, Pre-Punching Ntaus, Pre-Cutting Device, Hydraulic Chaw Nres Tsheb, PLC Tswjhwm, Txhawb Lub Rooj. |

| 2. | Tswj System | PLC Inverter Encoder Kov Screen |

| 3. | Main Ncej | 400 hli H-Beam |

| 4. | Tag Nrho Lub Zog | 22 kwv |

| 5. | Fais fab mov | 380V, 3-phase, 50Hz |

| 6. | Txoj kev ceev | 12-24m / min |

| 7. | Roll chaw nres tsheb | 18 sawv |

| 8. | Roller Diameter | 80 hli |

| 9. | Siv dav dav | 80-300 hli |

| 10. | Pub Thickness | 1.5-3.0 hli |

| 11. | Backboard Thickness | 20 hli |

| 12. | Cutter Standard | GCr12 |

| 13. | Roller Standard | Gcr15# |

| 14. | Zuag qhia tag nrho | Txog 8500 × 1000 × 1400mm |

| 15. | Qhov hnyav tag nrho | Txog 10T |

| 16. | Kev cai | Raws li cov neeg siv khoom xav tau |

表格宽度最宽为750,超过750的部分及内就了均无法展示

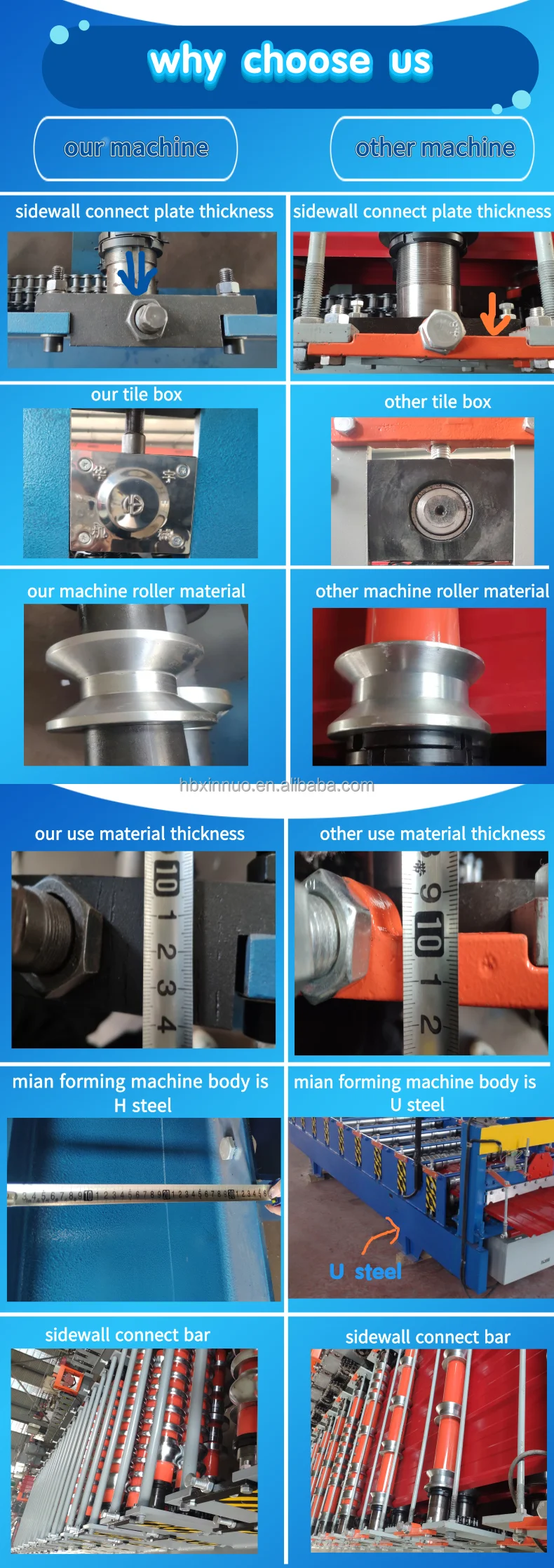

Vim Li Cas Xaiv Peb

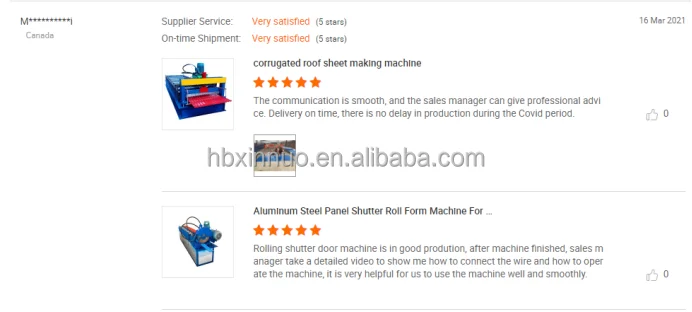

Cov neeg siv tshuaj xyuas

Packing & Delivery

| Ntim Cov Lus Qhia: | Lub tshuab tseem ceeb yog liab qab, lub computer tswj lub thawv yog ntim nrog ntoo ncej. |

| Lub tshuab tseem ceeb yog liab qab nyob rau hauv lub thawv, lub computer tswj lub thawv yog ntim nrog ntoo ntim. | |

| Delivery Detail: | 20 hnub |

cz purlin yob txoj kev tshuab ntawm Tuam Tshojcz seem purlin txias cov menyuam tshuab

Peb Qhov Zoo

LARGE CNC milling tshuab

cz purlin yob txoj kev tshuab ntawm Tuam Tshoj cz seem purlin txias cov menyuam tshuab ib tug tshwj xeeb cog nyob rau hauv Hebei Province.It ncaj qha mills tag nrho cov ncej. Lub tshuab milling tuaj yeem ua rau lub tshuab loj nto smoother thiab lub tshuab zoo dua qub. cz purlin yob txoj kev tshuab ntawm Tuam Tshoj cz seem purlin txias cov menyuam tshuab

MUAB BLASTING MACHINE

cz purlin yob txoj kev tshuab ntawm Tuam Tshoj cz seem purlin txias cov menyuam tshuab tuaj yeem tuav tag nrho lub tshuab thav duab los yog qhov chaw, ua rau lub rusty nto huv si thiab du Lub nto ntawm cov khoom nce adhesion.cz purlin yob txoj kev tshuab ntawm Tuam Tshoj cz seem purlin txias roller tshuab

TSHIAB CNC milling

cz purlin yob txoj kev tshuab ntawm Tuam Tshoj cz seem purlin txias cov menyuam tshuab ua lub backboard ntawm purlin tshuab, kuj ua rau lub qhov ntawm backboard. Lub tshuab milling no tuaj yeem milling lub backboard ntau qib, qhov chaw qhov muaj nqi ntau dua. Qhov no tuaj yeem ua rau cov menyuam yaus ntau qib tom qab kev txhim kho, thiab tom qab ntawd cov purlin yuav ncaj dua.

Mechanical txheej txheem

cz purlin yob txoj kev tshuab ntawm Tuam Tshoj cz seem purlin txias rau cov menyuam tshuab kab, muaj siab zoo CNC grinders thiab milling tshuab, ua rau cov chais thiab shafts ntawm lub tshuab.Tom qab tsim, muaj cov kws tshaj lij engineer los xyuas seb cov no tsim nyog. rau ib lub tshuab, peb ua txhua kauj ruam ua tib zoo kom paub tseeb tias qhov zoo.

ELECTRICAL CONTROL

Tag nrho cov tswj system ntawm peb cov cav tov peb

ua los ntawm peb tus kheej. peb muaj tus kws tshaj lij engineer los tsim thiab ua qhov kev tswj hwm. cz purlin yob txoj kev tshuab ntawm Tuam Tshoj cz seem purlin txias cov menyuam tshuab tuaj yeem ua kom cov kev pab cuam tom qab muag, thaum cov neeg siv khoom muaj teeb meem nrog kev tswj xyuas, peb tuaj yeem daws tau raws sijhawm.

Environmental phooj ywg SPRAYING EQUIPMENT

cz purlin yob txoj kev tshuab ntawm Tuam Tshoj cz seem purlin txias cov menyuam tshuab electrostatic txau cov cuab yeej ua tau raws li kev tiv thaiv ib puag ncig ntawm tsoomfwv Suav thiab lav lub sijhawm xa khoom ntawm lub tshuab.

Tuam txhab Profile

FAQ

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., tsis tsuas yog tsim ntau hom kev yob txoj kev tshuab, tab sis kuj tsim cov ntse tsis siv neeg yob txoj kab ntau lawm, C & Z puab purline tshuab, txoj kev loj guardrail yob txoj kev tshuab kab, sandwich vaj huam sib luag ntau lawm kab, decking kev tsim cov cav tov, lub teeb keel tshuab, shutter slat door forming machines, downpipe machines, gutter machine, etc.

Qhov zoo ntawm Roll Forming Ib Qhov Hlau

Muaj ntau qhov zoo ntawm kev siv yob txoj kev rau koj cov haujlwm:

- Cov txheej txheem yob txoj kev tso cai rau kev ua haujlwm xws li xuas nrig ntaus, txiav, thiab vuam kom ua tiav hauv kab. Tus nqi ua haujlwm thiab lub sijhawm rau kev ua haujlwm thib ob raug txo lossis tshem tawm, txo cov nqi ib feem.

- Roll form tooling tso cai rau kom muaj kev hloov pauv siab. Ib txheej txheej ntawm yob daim ntawv cov cuab yeej yuav ua rau yuav luag txhua qhov ntev ntawm tib ntu ntu. Ntau cov cuab yeej siv rau qhov sib txawv qhov ntev tsis tas yuav tsum tau ua.

- Nws tuaj yeem muab kev tswj kom zoo dua li lwm cov txheej txheem hlau sib tw.

- Repeatability yog nyob rau hauv tus txheej txheem, tso cai yooj yim los ua ke ntawm yob tsim qhov chaw rau hauv koj cov khoom tiav, thiab txo cov teeb meem vim "tus qauv" kam rau ua.

- Roll forming feem ntau yog txheej txheem ceev dua.

- Roll forming muab cov neeg siv khoom zoo tshaj qhov ua tiav. Qhov no ua rau yob txoj kev xaiv zoo tshaj plaws rau cov hniav stainless hlau qhov chaw los yog rau qhov chaw uas yuav tsum tau ua tiav xws li anodizing lossis hmoov txheej. Tsis tas li ntawd, kev ntxhib los mos los yog qauv tuaj yeem dov rau hauv qhov chaw thaum tsim.

- Roll forming siv cov khoom siv tau zoo dua li lwm cov txheej txheem sib tw.

- Roll tsim cov duab tuaj yeem tsim nrog cov phab ntsa nyias dua li cov txheej txheem sib tw

Roll forming yog txheej txheem tas mus li uas hloov cov ntawv hlau mus rau hauv ib qho kev tsim qauv siv cov txheej txheem sib law liag ntawm cov rolls, txhua qhov ua rau tsuas yog hloov pauv hauv daim ntawv. Cov txiaj ntsig ntawm cov kev hloov me me hauv daim ntawv no yog qhov nyuaj profile.

-

CZ purlin yob txoj kev tshuab

-

gutter yob txoj kev tshuab

-

hudraulic decoiler

-

Tsis siv neeg qab nthab t-grid zoo li tus steel bar fram ...

-

Xinnuo shutter qhov rooj tshuab hlau dov ...

-

tsis siv neeg c stud yob txoj kev tshuab c channel ...

-

tsis siv neeg daim ntawv decoiler tshuab vuas cutter m ...

-

tsis siv neeg stacker

-

chim corrugated hlau ntawv ua tshuab ntsib ...

-

c profile steel yob txoj kev tshuab pib cz s ...

-

tshuab curving

-

ob txheej yob txoj kev tshuab

-

cz purlin yob txoj kev tshuab yob txoj kev mac ...

-

qhov rooj ncej yob txoj kev tshuab

-

cz purlin yob txoj kev tshuab hlau ntawv makin ...

-

ob txheej yob txoj kev tshuab yob txoj kev ...