Cable ladder tais ua tshuab hlau yob txoj kev tshuab hlau ntawv ua tshuab hlau vov tsev cov cav tov rau kev muag khoom

Cable ladder tais ua tshuab yig nqe

Cov khoom siv: Phau ntawv uncoiler, Roll forming tshuab, computer tswj system, hydraulic tswj system, txiav, khiav tawm rooj

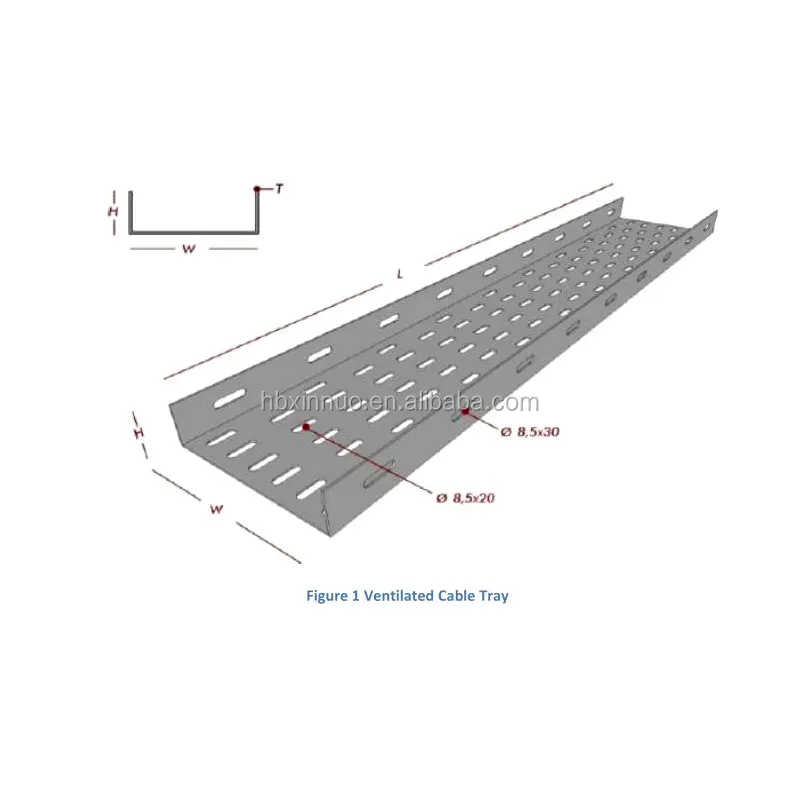

Main parameter Cable ladder tais ua tshuab yig nqe

| Tsis muaj. | Cable ladder tais ua tshuab yig nqe | ||

| 1 | Haum rau kev ua haujlwm | Xim hlau phaj | |

| 2 | Dav ntawm lub phaj | 300-900 hli | |

| 3 | Rollers | 18-22 : kuv | |

| 4 | Qhov ntev | 10.5 * 1.6 * 1.5m | |

| 5 | Hwj chim | 11 + 4kw | |

| 6 | Thickness ntawm lub phaj | 0.5-1.2 hli | |

| 7 | Productivity | 4-6m / min | |

| 8 | Txoj kab uas hla ntawm cov menyuam | 90mm ua | |

| 9 | Qhov hnyav | 8,0 t | |

| 10 | Qhov hluav taws xob | 380V 50Hz 3 theem | |

| 11 | Rolling khoom | Cov pa roj carbon steel 45 # | |

| 12 | Khoom siv ntawm lub phaj txiav | Cr 12 | |

| 13 | Ua precision | Hauv 1.00mm | |

| 14 | Tswj qhov system | PLC tswj | |

Cable ladder tais ua tshuab yig nqe

1) Decoiler

Decoiler Hom: phau ntawv decoiler

Qhov hnyav ntawm decoiler: 5.0T

2) Khoom noj khoom haus thiab qib qib

Nws siv los ua cov khoom tiaj tus ua ntej pub rau hauv lub tshuab yob txoj kev

3) Punching thiab txiav Device

Cable ladder tais ua tshuab yig nqe

Nws siv rau xuas nrig ntaus lub qhov haum thiab txiav rau lub hom phiaj ntev ntawm cov khoom.

Punching Hom: Hydraulic Punching

Txiav hom: Hydraulic txiav

Cov khoom siv: Cr12

Hydraulic zog: 5.5KW

Hydraulic siab: 16 Mpa

4) Rolling Forming System

Lub cev muaj zog hom: theem asynchronous lub cev muaj zog (chaw tsim tshuaj paus: shanghai nanyang)

Lub cev muaj zog: 15KW

kev sib sau ceev: 10-14.8m / min

Khoom siv ntawm cov menyuam: GCr15

18 pawg rollers

Cov khoom siv ntawm lub ntsiab ncej: 40Cr (Lub ntsiab ncej muaj qhov sib tsoo ntau zaus & Kev kho cua sov thiab qhov chaw ntawm ncej yog chroming)

Txoj kab uas hla ntawm lub ntsiab ncej: ø70mm

5) PLC tswj qhov system

Tswj kom muaj nuj nqis & punching ntev & txiav ntev txiav

Voltage: 380V, 3 Phase 50Hz

Loj ntawm PLC Tswjhwm: 700mm (L) x 1000mm (H) x 300mm (W)

PLC chaw tsim tshuaj paus: Nyiv Panasonic

Solenoid valve

Roj hydraulic lub tog raj kheej

Cov kabmob

Roj kav dej

Kov npo

Encoder

6) Cov khoom txhawb nqa ncej

Qhov ntev ntawm cov khoom txhawb nqa ncej: 6m

Cable ladder tais ua tshuab yig nqe

Cable ladder tais ua tshuab yig nqe

| Peb lub tshuab | Kev cuam tshuam ntawm lub tshuab | |

| Main formingmachine lub cev | Siab zogH300los yog H350 steel.tshuab los ntawm milling tshuab afterwelding | Sturdy thiab check, xyuas kom meej cov qauv phaj |

| Cov khoom siv ntawm cov menyuam | GCr15 | Xyuas kom meej tias cov nyhuv tsim ntawm lub vaj huam sib luag thiab lub hnub nyoog siv yuav ntev dua, qhov chaw ntawm lub vaj huam sib luag |

| Material ntawm kev txiav | Cr12 steel nrog quenched kev kho mob | Txiav tawm ntawm cov duab tsis yooj yim thiab siv lub hnub nyoog yuav ntev dua, lub panelsize precision |

| Khoom siv ntawm lub cev muaj zog | High qib No.45 forged steel,Ncej diameter yog80o75 ibmm. | Txhim kho qhov kev sib xyaw ua ke ntawm tus ncej thiab khaws cov khoom lag luam |

| Tswj qhov system | PLC tswj qhov system, qee cov khoom yog imported los ntawm Nyiv thiab lub teb chaws Yelemees | Tshuab ua qhov tseeb thiab ruaj khov dua |

Hebei Xinnuo Roll Forming Machine Co., Ltd., tsis tsuas yog tsim ntau hom kev yob txoj kev tshuab, tab sis kuj tsim cov ntse tsis siv neeg yob txoj kab ntau lawm, C & Z puab purline tshuab, txoj kev loj guardrail yob txoj kev tshuab kab, sandwich vaj huam sib luag ntau lawm kab, decking kev tsim cov cav tov, lub teeb keel tshuab, shutter slat door forming machines, downpipe machines, gutter machine, etc.

Cable ladder tais ua tshuab yig nqe

Peb cov cav tov muaj qhov zoo nkauj zoo nkauj, lub neej ua haujlwm ntev, kev ua haujlwm zoo, kev ua haujlwm yooj yim, tus nqi tsim nyog, zoo zoo thiab lwm yam.

Cov kev pabcuam muaj zog yog qhov ruaj khov tshaj plaws rau peb cov khoom zoo. Peb txais kev siv computer software rau kev tsim duab kos duab, kos duab tsim thiab kos duab rau cov khoom siv steel. Peb tau txais kev soj ntsuam zoo hauv computer digital thiab tsim cov khoom siv hluav taws xob zoo zoo. Peb cov txuj ci tau hloov kho txhua hnub! Cable ladder tais ua tshuab yig nqe

Peb lub tuam txhab muaj matured tom qab-muag kev pab cuam network,peb tuaj yeem muab kev pabcuam zoo thiab txaus siab rau koj thoob plaws lub sijhawm ntawm peb txoj kev koom tes.Yog tias tsim nyog, peb tuaj yeem muab kev pabcuam rau koj hauv zos thiab xa cov kws tshaj lij rau kev teeb tsa thiab kev cob qhia ua haujlwm.

Cov ntsiab lus ntawm Kev Them Nyiaj: 30% ntawm tag nrho cov nqi cog lus them los ntawm T / T raws li kev them nqi, tshuav 70% ntawm tag nrho cov nqi cog lus yuav tsum tau them los ntawm T / T tom qab tshuaj xyuas los ntawm tus neeg yuav khoom hauv lub Hoobkas thaum ua ntej xa khoom.

Tus me nyuam: 30 hnub tom qab tau txais cov nyiaj them ua ntej

Kev Pabcuam: peb xa cov kws tshaj lij rau koj lub tebchaws los kho lub tshuab.Tus neeg yuav khoom yuav tsum tau them tag nrho cov nqi suav nrog: vixaj, daim pib mus ncig thiab kev pabcuam tsim nyog, tus neeg yuav khoom yuav tsum them nyiaj hli 80USD / hnub.

Warranty: 12 lub hlis txwv warranty

Thaum lub sij hawm warranty: cov khoom yog dawb tab sis tus neeg yuav khoom them tus nqi xa khoom.

Cable ladder tais ua tshuab yig nqe

1: Yuav ua li cas ua si xaj:

Kev nug - paub meej cov duab kos duab thiab tus nqi - paub meej PI - teem caij tso nyiaj lossis L / C - ces OK

2: Yuav ua li cas mus ntsib peb lub tuam txhab:

ya mus rau Beijing tshav dav hlau: Los ntawm kev kub ceev tsheb ciav hlau Los ntawm Beijing Nan mus rau Cangzhou Xi (1 teev), ces peb tuaj tos koj.

ya mus rau Shanghai tshav dav hlau: Los ntawm kev kub ceev tsheb ciav hlau Los ntawm Shanghai Hongqiao rau Cangzhou Xi (4.5 teev), ces peb tuaj tos koj.

3: Thaum peb xa tawm cov tshuab:

Peb tau ua thiab xa tawm cov tshuab txij li xyoo ntawmXyoo 1998.

4.Dab tsi yog qhov kev pab cuam tom qab muag:

peb tau xa cov kws tshaj lij rau koj lub tebchaws los kho lub tshuab.Tus neeg yuav khoom yuav tsum dais tag nrho cov nqi suav nrog:

vixaj, daim pib mus ncig ua si thiab kev pabcuam tsim nyog, tus neeg yuav khoom yuav tsum them nyiaj hli 80USD / hnub.

5.Yuav ua li cas txog lub warranty:12 hlitxwv warranty

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., tsis tsuas yog tsim ntau hom kev yob txoj kev tshuab, tab sis kuj tsim cov ntse tsis siv neeg yob txoj kab ntau lawm, C & Z puab purline tshuab, txoj kev loj guardrail yob txoj kev tshuab kab, sandwich vaj huam sib luag ntau lawm kab, decking kev tsim cov cav tov, lub teeb keel tshuab, shutter slat door forming machines, downpipe machines, gutter machine, etc.

Qhov zoo ntawm Roll Forming Ib Qhov Hlau

Muaj ntau qhov zoo ntawm kev siv yob txoj kev rau koj cov haujlwm:

- Cov txheej txheem yob txoj kev tso cai rau kev ua haujlwm xws li xuas nrig ntaus, txiav, thiab vuam kom ua tiav hauv kab. Tus nqi ua haujlwm thiab lub sijhawm rau kev ua haujlwm thib ob raug txo lossis tshem tawm, txo cov nqi ib feem.

- Roll form tooling tso cai rau kom muaj kev hloov pauv siab. Ib txheej txheej ntawm yob daim ntawv cov cuab yeej yuav ua rau yuav luag txhua qhov ntev ntawm tib ntu ntu. Ntau cov cuab yeej siv rau qhov sib txawv qhov ntev tsis tas yuav tsum tau ua.

- Nws tuaj yeem muab kev tswj kom zoo dua li lwm cov txheej txheem hlau sib tw.

- Repeatability yog nyob rau hauv tus txheej txheem, tso cai yooj yim los ua ke ntawm yob tsim qhov chaw rau hauv koj cov khoom tiav, thiab txo cov teeb meem vim "tus qauv" kam rau ua.

- Roll forming feem ntau yog txheej txheem ceev dua.

- Roll forming muab cov neeg siv khoom zoo tshaj qhov ua tiav. Qhov no ua rau yob txoj kev xaiv zoo tshaj plaws rau cov hniav stainless hlau qhov chaw los yog rau qhov chaw uas yuav tsum tau ua tiav xws li anodizing lossis hmoov txheej. Tsis tas li ntawd, kev ntxhib los mos los yog qauv tuaj yeem dov rau hauv qhov chaw thaum tsim.

- Roll forming siv cov khoom siv tau zoo dua li lwm cov txheej txheem sib tw.

- Roll tsim cov duab tuaj yeem tsim nrog cov phab ntsa nyias dua li cov txheej txheem sib tw

Roll forming yog txheej txheem tas mus li uas hloov cov ntawv hlau mus rau hauv ib qho kev tsim qauv siv cov txheej txheem sib law liag ntawm cov rolls, txhua qhov ua rau tsuas yog hloov pauv hauv daim ntawv. Cov txiaj ntsig ntawm cov kev hloov me me hauv daim ntawv no yog qhov nyuaj profile.

-

tshuab leveling

-

shutter qhov rooj yob txoj kev tshuab

-

C21 hom pobzeb xovxwm Rooj vaj huam sib luag yob txoj kev mac ...

-

tsis siv neeg yob txoj kev tshuab nqe chim cor ...

-

Tsis siv neeg qab nthab t-grid zoo li tus steel bar fram ...

-

tsis siv neeg daim ntawv decoiler tshuab vuas cutter m ...

-

chim corrugated ru tsev ntawv ua tshuab sup ...

-

khoov tshuab

-

tshuab curving

-

corrugated vaj huam sib luag yob txoj kev tshuab

-

txiav tshuab

-

Pem Teb Decking Panels Yob txoj Tshuab Hlau ...

-

Pem Teb Decking Roll Forming Tshuab

-

High Quality yob txoj kev tshuab rau tub rau khoom swb

-

Glazed zinc pob zeb txheej ru tsev antique vuas co ...

-

Txoj Kev Loj Guardrail Roll Forming Tshuab