Product Description

| TSIS MUAJ. | Lub ntsiab parameter ntawm Botou nroog canton ncaj ncees authentication 828 automatoc xovxwm xiav ua glazed joists steel ru tsev pobzeb yob los ntawm lub tshuab nrog ce | |

| 1 | Haum rau kev ua haujlwm | Xim hlau phaj |

| 2 | Dav ntawm lub phaj | 1000 hli |

| 3 | Thickness ntawm lub phaj | 0.3-0.7 hli |

| 4 | De-coiler | Phau ntawv ib, tuaj yeem thauj khoom 5 tons raw khoom |

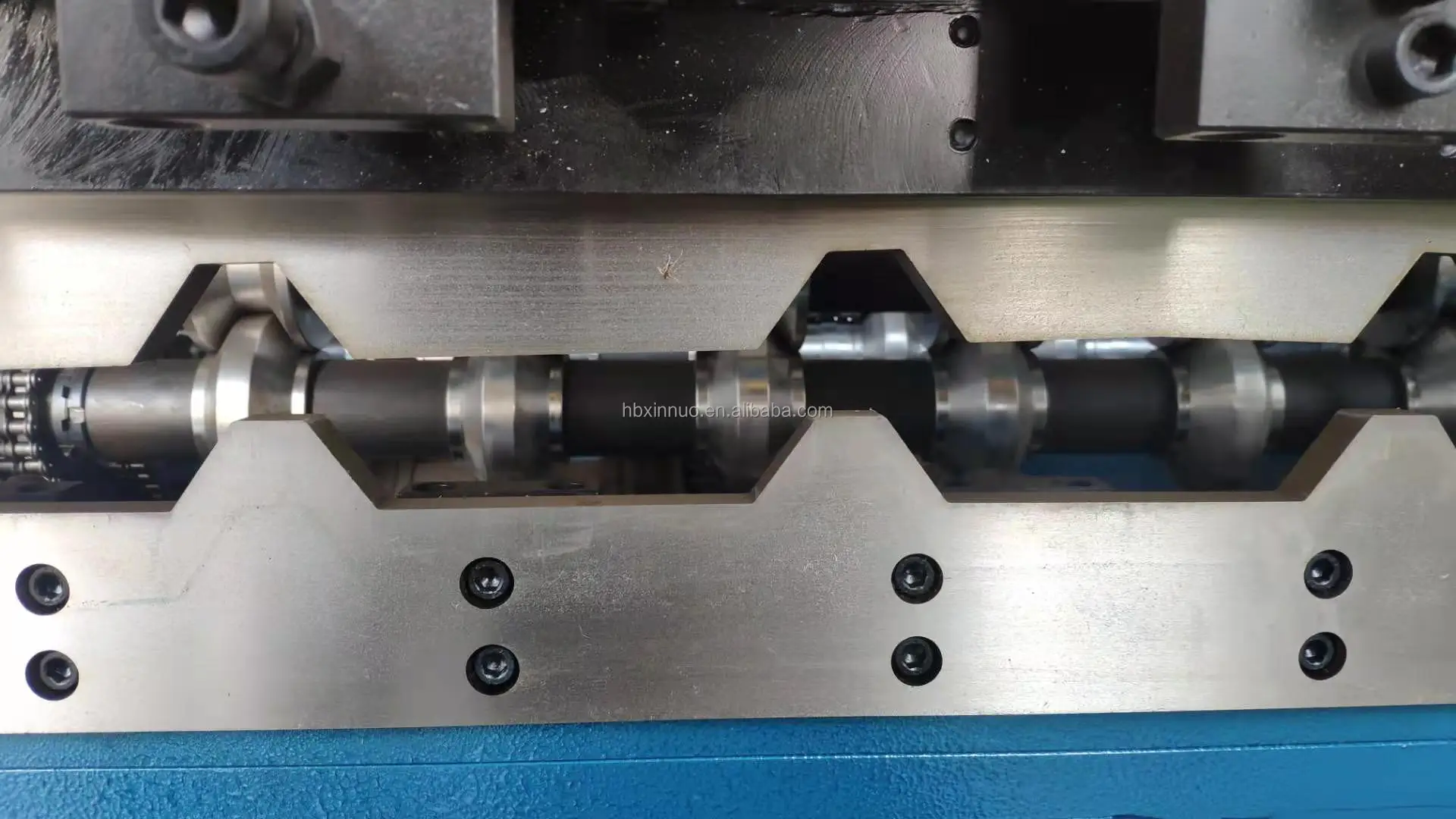

| 5 | Rollers rau txoj kev | 12 row |

| 6 | Txoj kab uas hla ntawm cov menyuam | 80 hli |

| 7 | Rolling khoom | Cov pa roj carbon steel 45 # |

| 8 | Main lub cev muaj zog | 4 kwv |

| 9 | Productivity | 0-3m / min |

| 10 | Txiav txoj kev | Hydraulic thiab coj ncej txiav |

| 11 | Cov khoom ntawm cov hniav txiav | Cr 12 |

| 12 | Hydraulic txiav fais fab | 3 kwv |

| 13 | Ua precision | Hauv 1.00mm |

| 14 | Tswj qhov system | Delta PLC tswj |

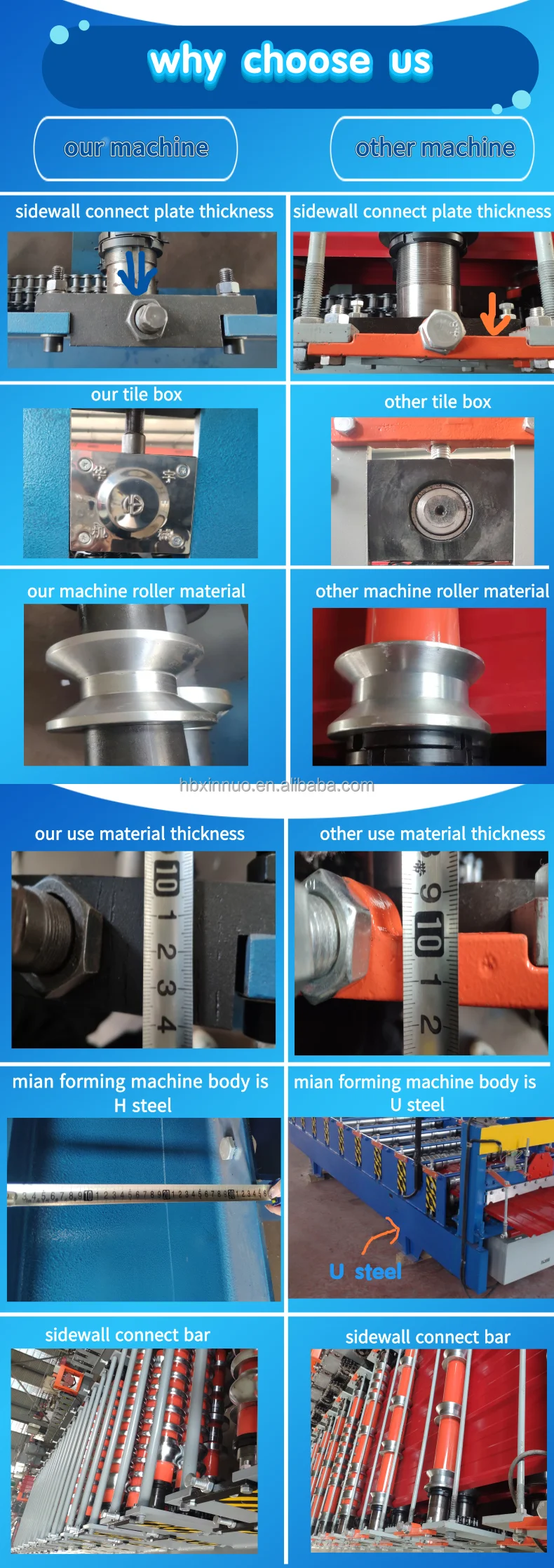

| 15 | Sab vaj huam sib luag ntawm lub tshuab | 14mm ib |

| 16 | Lub ntsiab qauv ntawm lub tshuab | 300 H hlau |

| 17 | Qhov hnyav | Txog 4.0T |

| 18 | Qhov ntev | Loj: 7.0 * 1.5 * 1.55m |

| 19 | Qhov hluav taws xob | 380V 50Hz 3phases (hloov tau raws li xav tau) |

| 20 | Daim ntawv pov thawj | CE / ISO |

| 21 | Kev cai | Raws li cov neeg siv khoom xav tau |

Packing & Delivery

| Ntim Cov Lus Qhia: | Lub tshuab tseem ceeb yog liab qab, lub computer tswj lub thawv yog ntim nrog ntoo ncej. |

| Lub tshuab tseem ceeb yog liab qab nyob rau hauv lub thawv, lub computer tswj lub thawv yog ntim nrog ntoo ntim. | |

| Delivery Detail: | 20 hnub |

Tuam txhab Profile

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., tsis tsuas yog tsim ntau hom kev yob txoj kev tshuab, tab sis kuj tsim cov ntse tsis siv neeg yob txoj kab ntau lawm, C & Z puab purline tshuab, txoj kev loj guardrail yob txoj kev tshuab kab, sandwich vaj huam sib luag ntau lawm kab, decking kev tsim cov cav tov, lub teeb keel tshuab, shutter slat door forming machines, downpipe machines, gutter machine, etc.

Qhov zoo ntawm Roll Forming Ib Qhov Hlau

Muaj ntau qhov zoo ntawm kev siv yob txoj kev rau koj cov haujlwm:

- Cov txheej txheem yob txoj kev tso cai rau kev ua haujlwm xws li xuas nrig ntaus, txiav, thiab vuam kom ua tiav hauv kab. Tus nqi ua haujlwm thiab lub sijhawm rau kev ua haujlwm thib ob raug txo lossis tshem tawm, txo cov nqi ib feem.

- Roll form tooling tso cai rau kom muaj kev hloov pauv siab. Ib txheej txheej ntawm yob daim ntawv cov cuab yeej yuav ua rau yuav luag txhua qhov ntev ntawm tib ntu ntu. Ntau cov cuab yeej siv rau qhov sib txawv qhov ntev tsis tas yuav tsum tau ua.

- Nws tuaj yeem muab kev tswj kom zoo dua li lwm cov txheej txheem hlau sib tw.

- Repeatability yog nyob rau hauv tus txheej txheem, tso cai yooj yim los ua ke ntawm yob tsim qhov chaw rau hauv koj cov khoom tiav, thiab txo cov teeb meem vim "tus qauv" kam rau ua.

- Roll forming feem ntau yog txheej txheem ceev dua.

- Roll forming muab cov neeg siv khoom zoo tshaj qhov ua tiav. Qhov no ua rau yob txoj kev xaiv zoo tshaj plaws rau cov hniav stainless hlau qhov chaw los yog rau qhov chaw uas yuav tsum tau ua tiav xws li anodizing lossis hmoov txheej. Tsis tas li ntawd, kev ntxhib los mos los yog qauv tuaj yeem dov rau hauv qhov chaw thaum tsim.

- Roll forming siv cov khoom siv tau zoo dua li lwm cov txheej txheem sib tw.

- Roll tsim cov duab tuaj yeem tsim nrog cov phab ntsa nyias dua li cov txheej txheem sib tw

Roll forming yog txheej txheem tas mus li uas hloov cov ntawv hlau mus rau hauv ib qho kev tsim qauv siv cov txheej txheem sib law liag ntawm cov rolls, txhua qhov ua rau tsuas yog hloov pauv hauv daim ntawv. Cov txiaj ntsig ntawm cov kev hloov me me hauv daim ntawv no yog qhov nyuaj profile.

-

Siab Zoo rau Tuam Tshoj Hnub Ci Vaj Huam Sib Luag Txhuas PV ...

-

Zoo zoo Tuam Tshoj Hlau Glazed Roofing Pobzeb Ro ...

-

Factory Supply Automatic Roll Forming Mac...

-

Hoobkas ncaj qha Tuam Tshoj Xim Hlau Hlau laj kab ...

-

Factory Supply Xinnuo Txawv Thickness Highw ...

-

Tus nqi tsim nyog rau Tuam Tshoj Tsis Siv Neeg Trapezoida ...