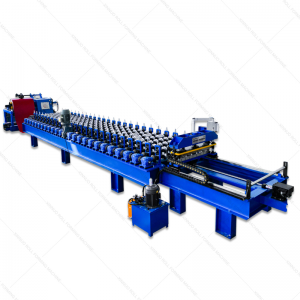

Tshiab Tsim Xinnuo Kub Muag High Speed Light Gauge Hlau KeelCold Roll Forming Tshuab,

Cold Roll Forming Tshuab, kev kub ceev, kub muag.lub teeb keel, Hlau Roll Forming Tshuab, Xinnuo Roll Forming Tshuab, kev ceeb toom xyoo kawg.,

* Paub meej

lub teeb keel yob txoj kev tshuab tuaj yeem ua rau stud, taug qab thiab furring, Cov khoom no tsuas yog siv rau sab hauv kho kom zoo nkauj thav ntawv.

* Qhov zoo ntawm lub tshuab

1.Qhov tsim ntawm lub tshuab yog yooj yim los kho, rau nws muaj cov qauv tsim nyog, compact duab, siab precision thiab high efficiency.

2.Cov txheej txheem tsim khoom ntawm lub tshuab ua tiav yog nyob rau hauv nruj raws li cov qauv siv tshuab, taug qab thiab tswj kev tsim khoom ntawm txhua qhov chaw.

3.Professional pab neeg rau kev tshawb fawb thiab kev loj hlob, muab cov neeg siv nrog tsis siv neeg phaj ua cov khoom zoo thiab efficiency.

4.Cov kab tag nrho yog tswj nrog PLC, nrog kov npo ntawm cov zaub thiab kev ua haujlwm thiab siab automation.

* Qauv: C&U hom

| Tswj System | PLC Xim kov Screen |

| Main Ncej | 18mm steel vuam |

| Lub zog loj | 5.5 kwv |

| Fais fab mov | 380V, 3-Phase, 50Hz lossis lwm yam |

| Txoj kev ceev | 35-50m / min |

| Roll chaw nres tsheb | 10-12 teev |

| Ncej kab | 42-50 hli |

| Pub Thickness | 0.3-1.2 hli |

| Cutter Standard | Cr 12 |

| Roller Standard | 45 # Plating Cr |

* Cov duab nthuav dav

* Daim ntawv thov

Qhia Xinnuo Kub Muag High Speed Light Gauge Hlau Keel Txias Roll Forming Tshuab, koj qhov kev daws teeb meem kawg rau kev ua haujlwm zoo thiab meej hlau keel ntau lawm. Nrog kuv cov kev txawj ntse ua tus paub SEO thiab high-end eCommerce copywriter, kuv yuav nthuav qhia lub peev xwm txawv tshaj plaw ntawm lub tshuab muaj zog no, ntes nws cov ntsiab lus hauv 500-lo lus cov khoom piav qhia.

Tsim tshiab, Xinnuo Kub Muag Cold Roll Forming Tshuab embodies unrivaled ceev thiab precision. Zoo meej rau kev tsim lub teeb pom kev zoo hlau keels, cov cuab yeej siv no siv zog ua kom tau raws li koj qhov kev xav tau.

Nrog rau kev cog lus tsis tu ncua rau cov neeg siv khoom txaus siab, Xinnuo tau tsim lub tshuab uas hais ncaj qha rau koj cov kev xav tau. Los ntawm ua tib zoo nkag siab txog cov kev xav tau ntawm lawv cov neeg siv khoom, lawv tau tsim lub tshuab ua kom zoo tshaj plaws hauv daim ntawv thiab ua haujlwm.

Xinnuo Kub Muag High Speed Cold Roll Forming Tshuab tsis tsuas yog ua kom koj cov txheej txheem ntau lawm tab sis kuj ua kom zoo zoo. Nws cov thev naus laus zis tau lees paub qhov tseeb thiab seamless shaping ntawm hlau keels, tawm hauv qhov tsawg kawg nkaus rau qhov tsis raug lossis tsis zoo. Qhov tshwm sim? Cov khoom tsis zoo uas ua tau raws li cov qauv siab tshaj plaws, ua rau koj lub lag luam mus rau qhov siab tshiab.

Featuring ib tug intuitive interface thiab cov neeg siv-phooj ywg tswj, lub tshuab no enables yooj yim lag luam thiab teeb. Nws ergonomic tsim seamlessly sib txuas ua haujlwm nrog kev ua haujlwm, ua kom pom kev ua haujlwm zoo thaum txo qis qaug zog thaum siv txuas ntxiv. Tsuas yog ob peb kauj ruam yooj yim, koj tuaj yeem teeb tsa lub tshuab ua haujlwm, hloov cov ntaub ntawv raw rau hauv cov hlau keels zoo kawg nkaus.

Kev nyab xeeb yog qhov tseem ceeb tshaj plaws, thiab Xinnuo Kub Muag High Speed Cold Roll Forming Tshuab boasts ntau yam ntawm cov yam ntxwv los tiv thaiv ob tus neeg teb xov tooj thiab ib puag ncig ib puag ncig. Nruab nrog cov txheej txheem kev nyab xeeb siab heev, koj tuaj yeem so kom ntseeg tau tias kev sib tsoo thiab kev ua tsis zoo raug txo kom tsawg. Los ntawm qhov tseem ceeb ntawm kev nyab xeeb, Xinnuo qhia lawv txoj kev cog lus los muab kev lag luam-kev daws teeb meem rau koj txoj kev lag luam.

Versatility yog qhov tseem ceeb ntawm Xinnuo Kub Muag High Speed Cold Roll Forming Machine. Nrog customizable chaw thiab adaptability rau ntau yam hlau keel specifications, lub tshuab no muab koj txoj kev ywj pheej los tshawb nrhiav tsis muaj qhov kawg. Txawm hais tias koj xav tau cov thicknesses sib txawv los yog cov profiles, lub tshuab no tuaj yeem ua kom haum raws li koj cov kev xav tau tshwj xeeb, kom ntseeg tau qhov siab tshaj plaws rau koj cov kab ntau lawm.

Kev nqis peev hauv Xinnuo Kub Muag High Speed Cold Roll Forming Machine txhais tau tias kev nqis peev hauv kev ua haujlwm thiab kev tsim khoom. Los ntawm kev txo lub sijhawm ntau lawm thiab txhim kho cov khoom tsim tawm, lub tshuab no ua kom koj cov haujlwm ua haujlwm tau zoo, tso cai rau koj ua kom tau raws sijhawm nruj thiab nce koj cov txiaj ntsig. Nrog nws txoj kev ntseeg siab thiab kev ua tau zoo, koj tuaj yeem ntseeg siab coj koj txoj kev lag luam mus rau qhov siab tshiab, tawm hauv koj cov neeg sib tw.

Hauv kev xaus, Xinnuo Kub Muag High Speed Light Gauge Hlau Keel Txias Roll Forming Tshuab yog qhov hloov pauv hauv kev lag luam. Nws cov thev naus laus zis thev naus laus zis, tsim qauv siv tau zoo, thiab kev cog lus rau kev nyab xeeb ua rau nws yog qhov kev xaiv zoo tshaj plaws rau kev ua kom koj cov hlau keel ntau lawm. Nrog Xinnuo, koj tuaj yeem hla ciam teb thiab ua tiav zoo kawg nkaus. Kev nqis peev hauv Xinnuo Kub Muag High Speed Cold Roll Forming Tshuab hnub no, thiab ua tim khawv txog kev hloov pauv hauv koj lub lag luam.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., tsis tsuas yog tsim ntau hom kev yob txoj kev tshuab, tab sis kuj tsim cov ntse tsis siv neeg yob txoj kab ntau lawm, C & Z puab purline tshuab, txoj kev loj guardrail yob txoj kev tshuab kab, sandwich vaj huam sib luag ntau lawm kab, decking kev tsim cov cav tov, lub teeb keel tshuab, shutter slat door forming machines, downpipe machines, gutter machine, etc.

Qhov zoo ntawm Roll Forming Ib Qhov Hlau

Muaj ntau qhov zoo ntawm kev siv yob txoj kev rau koj cov haujlwm:

- Cov txheej txheem yob txoj kev tso cai rau kev ua haujlwm xws li xuas nrig ntaus, txiav, thiab vuam kom ua tiav hauv kab. Tus nqi ua haujlwm thiab lub sijhawm rau kev ua haujlwm thib ob raug txo lossis tshem tawm, txo cov nqi ib feem.

- Roll form tooling tso cai rau kom muaj kev hloov pauv siab. Ib txheej txheej ntawm yob daim ntawv cov cuab yeej yuav ua rau yuav luag txhua qhov ntev ntawm tib ntu ntu. Ntau cov cuab yeej siv rau qhov sib txawv qhov ntev tsis tas yuav tsum tau ua.

- Nws tuaj yeem muab kev tswj kom zoo dua li lwm cov txheej txheem hlau sib tw.

- Repeatability yog nyob rau hauv tus txheej txheem, tso cai yooj yim los ua ke ntawm yob tsim qhov chaw rau hauv koj cov khoom tiav, thiab txo cov teeb meem vim "tus qauv" kam rau ua.

- Roll forming feem ntau yog txheej txheem ceev dua.

- Roll forming muab cov neeg siv khoom zoo tshaj qhov ua tiav. Qhov no ua rau yob txoj kev xaiv zoo tshaj plaws rau cov hniav stainless hlau qhov chaw los yog rau qhov chaw uas yuav tsum tau ua tiav xws li anodizing lossis hmoov txheej. Tsis tas li ntawd, kev ntxhib los mos los yog qauv tuaj yeem dov rau hauv qhov chaw thaum tsim.

- Roll forming siv cov khoom siv tau zoo dua li lwm cov txheej txheem sib tw.

- Roll tsim cov duab tuaj yeem tsim nrog cov phab ntsa nyias dua li cov txheej txheem sib tw

Roll forming yog txheej txheem tas mus li uas hloov cov ntawv hlau mus rau hauv ib qho kev tsim qauv siv cov txheej txheem sib law liag ntawm cov rolls, txhua qhov ua rau tsuas yog hloov pauv hauv daim ntawv. Cov txiaj ntsig ntawm cov kev hloov me me hauv daim ntawv no yog qhov nyuaj profile.

-

Tsim qauv Xinnuo Ib puag ncig phooj ywg ...

-

Super Purchasing rau Tuam Tshoj Ibr Roofing Sheet Ir ...

-

Kub muag Hlau Stud thiab Track Roll Forming Mach ...

-

Tshiab zam tsim rau High Speed Light Keel St ...

-

Tuam Tshoj EPS Ua Npuas Ncauj Sandwich Vaj Huam Sib Luag Ntau Lawm Kab

-

Xinnuo IOS Certificate High Speed Xim Hlau M ...